Materials & Techniques

Premium Materials

At ChronoCrafters Atelier, we source only the finest materials from trusted suppliers worldwide. Our stainless steel components come from specialized foundries in Switzerland, known for their exceptional corrosion resistance and durability.

For our gold components, we use 18k gold alloys precisely formulated to maintain their luster while providing structural integrity. The sapphire crystals protecting our watch faces are laboratory-grown to achieve flawless transparency and extreme scratch resistance.

Our leather straps are crafted from premium European calfskin and exotic materials like alligator and ostrich, each piece carefully selected for its texture and grain pattern.

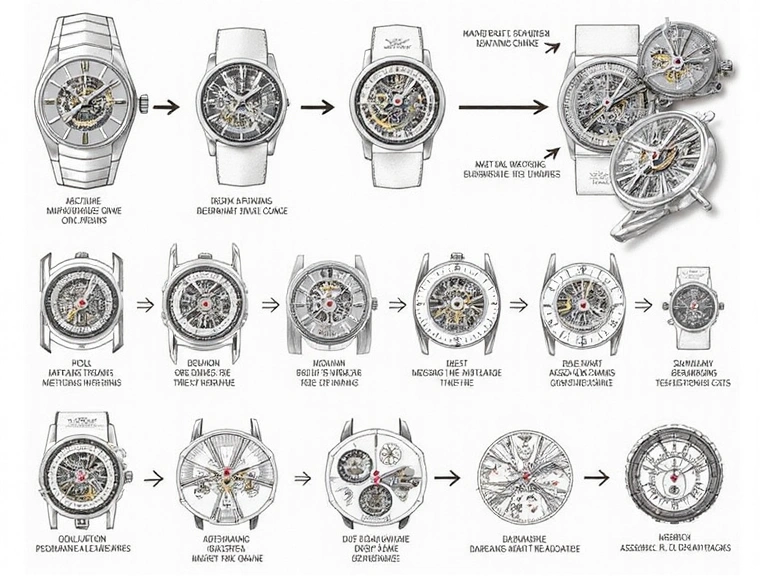

Traditional Techniques

Our master watchmakers employ time-honored techniques passed down through generations. Each movement is assembled by hand using specialized tools that allow for precision measured in hundredths of a millimeter.

The art of finishing involves techniques like perlage, Geneva stripes, and anglage - decorative patterns applied to movement components that also serve functional purposes by reducing friction and improving longevity.

We maintain traditional skills like hand-engraving and guilloché work, where intricate patterns are painstakingly cut into metal surfaces using antique rose engines and hand-operated lathes.

Movement Assembly

Each mechanical movement undergoes over 200 individual assembly steps, with components carefully lubricated and adjusted for optimal performance.

Case Finishing

Our cases receive up to 15 different finishing treatments, from initial sanding to final polishing, each performed by specialists in their respective techniques.

Quality Control

Every completed watch undergoes 30 days of continuous testing in multiple positions and environments to ensure chronometric excellence.

Innovation in Watchmaking

Modern Materials

While respecting tradition, we continually explore cutting-edge materials. Our proprietary ceramic alloys offer scratch resistance ten times greater than steel while being significantly lighter.

We've developed carbon composite cases that combine the strength of aerospace materials with the warmth of traditional watchmaking aesthetics. These advanced materials undergo the same meticulous finishing processes as our precious metal components.

Our research lab constantly tests new alloys and composites, working with material scientists to push the boundaries of what's possible in horological engineering.

Precision Engineering

Modern CNC machining allows us to create components with tolerances measured in microns, while still maintaining the hand-finished quality that defines our timepieces.

We've developed proprietary lubrication systems that maintain consistency across temperature variations, ensuring our movements perform equally well in arctic cold or desert heat.

Our anti-magnetic shielding technology protects movements from modern electromagnetic interference without compromising the traditional appearance of our watches.

The Art of Complications

Tourbillon

Our tourbillon mechanisms represent the pinnacle of mechanical watchmaking, with each requiring over 100 hours of assembly and adjustment by our most experienced watchmakers.

Perpetual Calendar

The perpetual calendar mechanisms we craft will correctly display the date through the year 2100 without manual adjustment, accounting for all leap years and month variations.

Minute Repeater

Our minute repeaters produce chimes of exceptional clarity, with each gong hand-tuned to perfection and the striking mechanism adjusted to millisecond precision.

Each complication we produce represents hundreds of hours of development and testing, combining centuries-old principles with modern manufacturing precision to create timepieces that are both technically brilliant and aesthetically magnificent.